Categories

UNITES Systems a.s.

Kpt. Macha 1372

757 01 Valašské Meziříčí

Czech republic

T: +420 571 757 230

E: e-mail contacts

Screening test of HVAC sensor

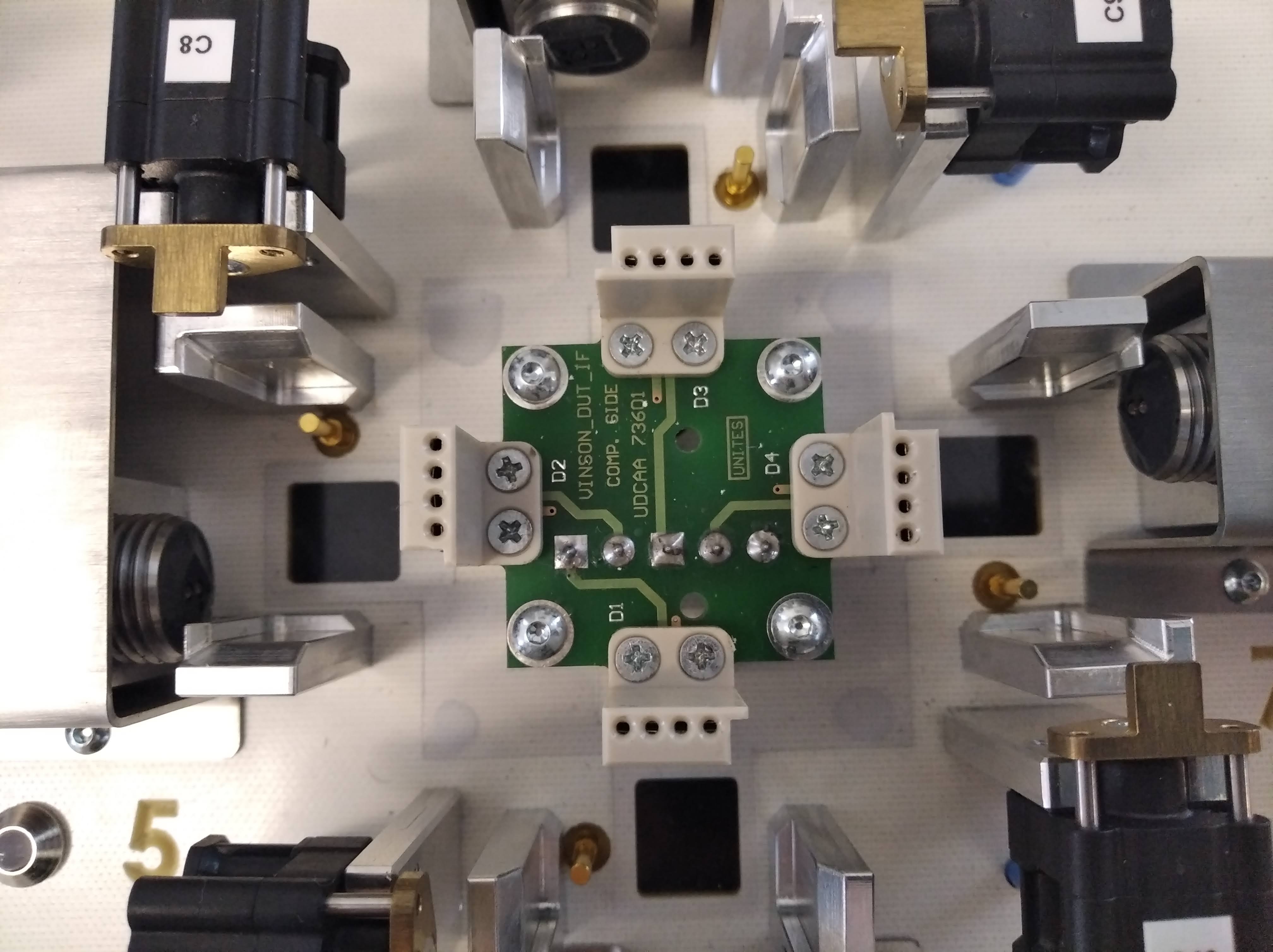

The tested product is a temperature sensor including a fan. This sensor is used as a feedback for automotive HVAC. We test the product at the end of the production process (End Of Line test) and in addition, 1% of production is tested in the climate chamber and in the sound cancelling chamber (Sample test).

End Of Line Test

The aim is to test 100% of product production in order to verify their basic functionality. The test must be very fast so as not to slow down the production process. To ensure a sufficient testing speed, 8 products are always measured simultaneously.

Measured values:

- 1-1.000.000RPM; 100ms evaluation; accuracy ± 10 RPM

- Current consumption measurement, Sampling 100Hz

- Voltage measurement Sampling 100Hz

Used HW

- Unites Desktop Moduler Tester

- Gantner Instruments Q.station XB Controller

- Gantner Instruments Q.bloxx Xl D101 8 inputs for pulse counting

- Gantner Instruments Q.bloxx XL A103 8 inputs for voltage

- Gantner Instruments Q.bloxx XL A105 4 inputs for Pt100

- TDK Lambda Z20-10-U

- Industrial PC

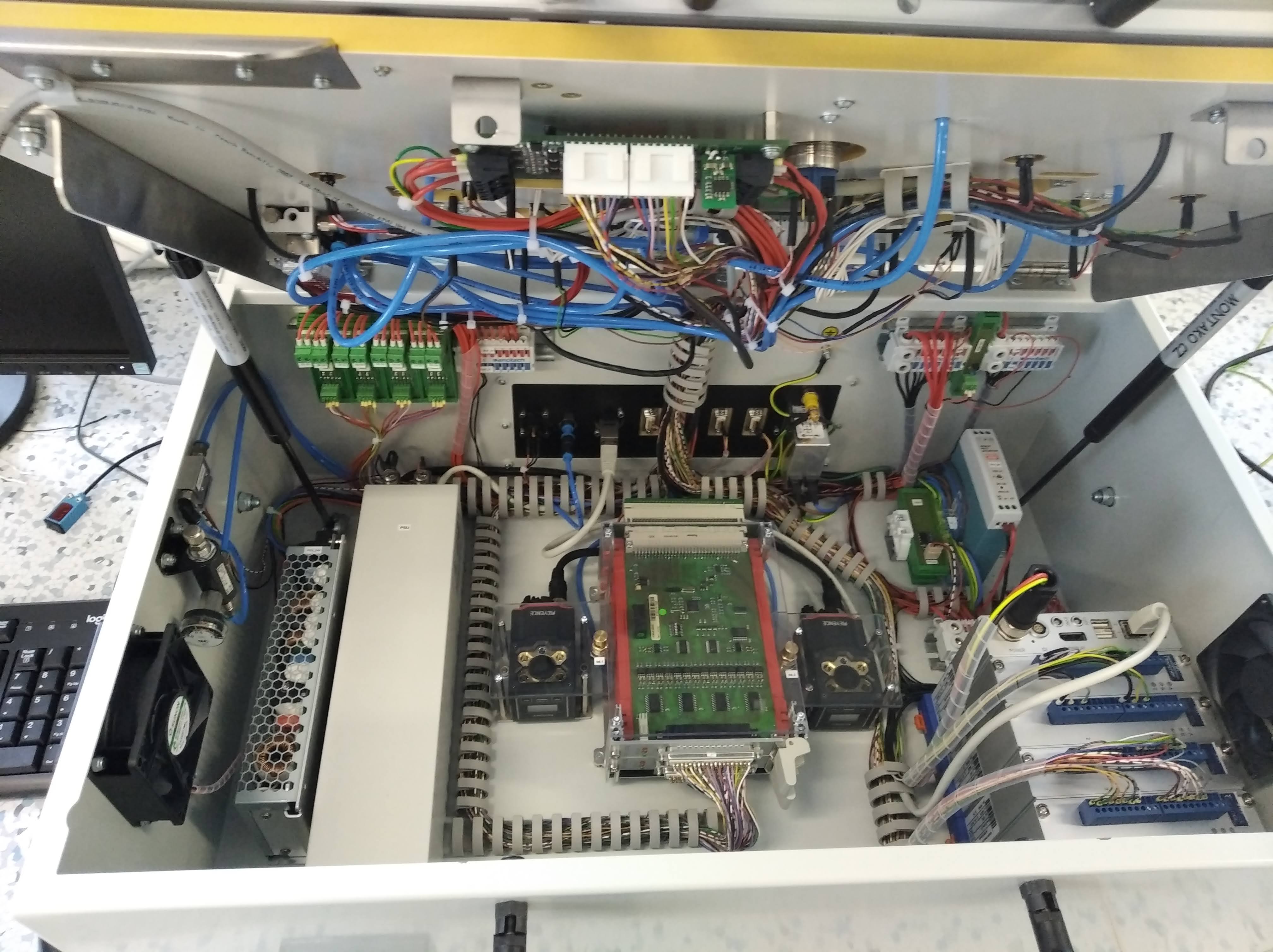

Sample test

Sound cancelling chamber

The aim of the measurement in the sound cancelling chamber is accurate testing of the acoustic properties of the product. The product is equipped with a fan that produces acoustic noise during operation. four products are placed in the chamber at the same time, but they are tested one by one. By placing four products at the same time, the handling time is reduced and the testing process becomes more efficient.

Measured values:

- Large dynamic range (120+ dB) and frequency range (5.6 Hz – 20 kHz)

- Sound levels up to 140 dB

- Simultaneous frequency weightings A/B, C, Z (linear) and time weightings F, S, I

- Back-erase – removes last 5 seconds of measurement data

- Broadband statistics based on LAeq, LAF or LAS

- Recording of measured signal during measurement

- FFT analysis

- Range 6 - 20kHz without peaks

- Central frequency 10kHz

- Speed 1-1.000.000RPM; 100ms evaluation; accuracy ± 10 RPM

HW:

- Unites Cabinet Modular Tester

- Unites Power Distribution Unit

- Gantner Instruments Q.station XB Controller

- Gantner Instruments Q.bloxx Xl D101 8 inputs for pulse counting

- Sound insulation chamber Studio Box

- Brüel & Kjær 2250

- TDK Lambda Z20-10-U

- VPC G6 interface

- Monarch IRS-W

- Industrial PC with UPS

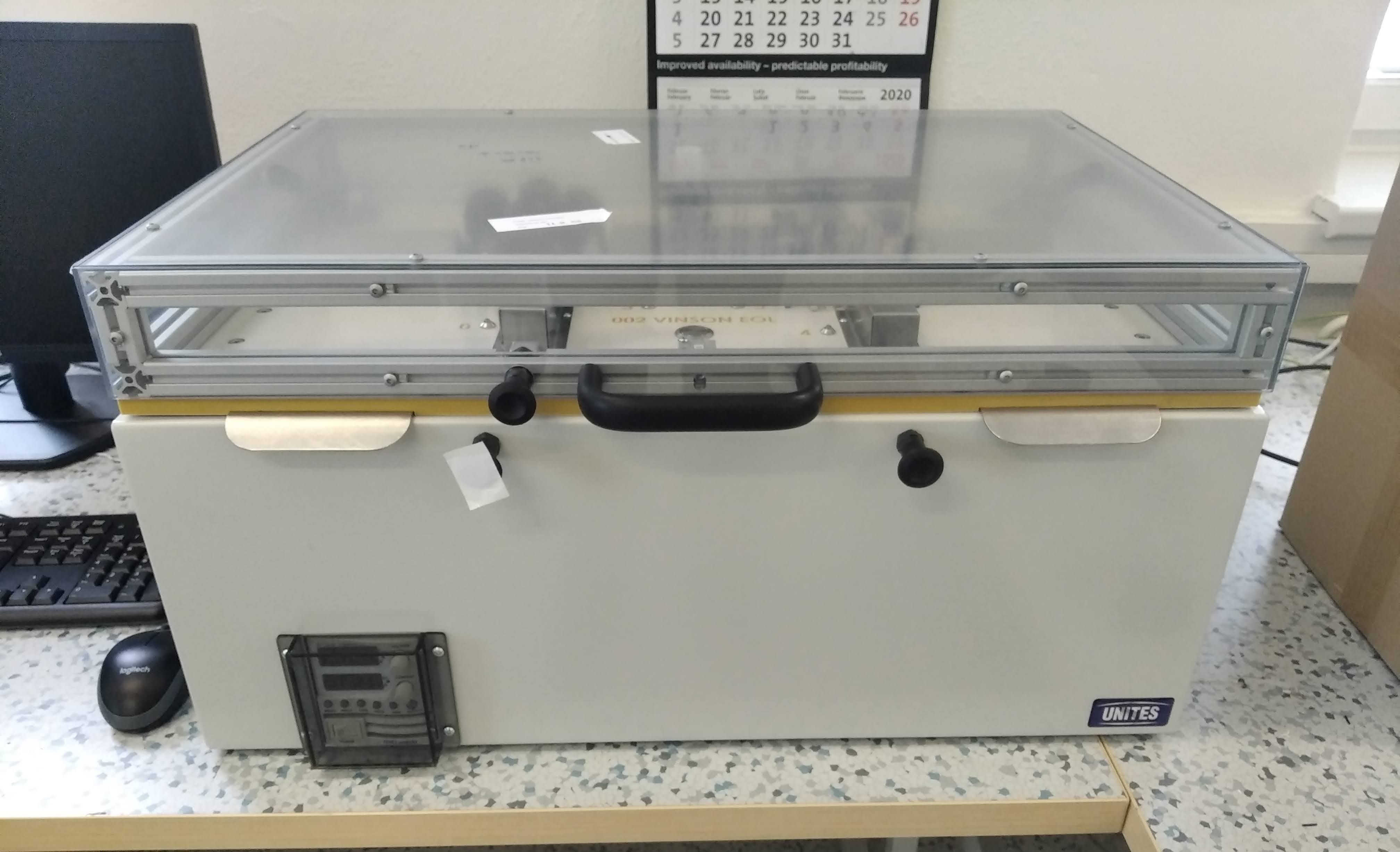

Climate Chamber Test

The aim of the test in the climatic chamber is to verify the correct functionality of the product in the temperature range from -20 ° C to + 80 ° C. Testing takes place at defined points of the temperature profile, usually after the product temperature has stabilized. The temperature profile lasts on the order of hours and during it the supply voltage changes. This tests the product for the limit conditions in which it must operate. To ensure the efficiency of the testing process, we test 32 pieces at a time.

Measured values:

- Temperature -40 +120

- Air drying possibility

- 120 dB dynamic range – up to 140 dB

- 24- or 16-bit recording of all or parts of a measurement

- Broadband and spectrum logging

- Logging profile display with markers

- Back-erase for manual delete of unwanted noise events

- FFT analysis

- Range 6 - 20kHz without peaks

- Central frequency 10kHz

- Speed 1-1.000.000RPM; 100ms evaluation; accuracy ± 10 RPM

Used HW:

- Unites Cabinet Modular Tester

- Unites Power Distribution Unit

- Clima Temperature Systeme CTS T-40/50 (-40°C +180°C)

- Brüel & Kjær 2250 L

- TDK Lambda Z20-10-U

- Keysight DMM 34465A

- VPC G6 interface

- Industrial PC with UPS

Contact: